GRI register

Strategy and analysis

G4-1 Statement from the most senior decisionmaker in the organization about the relevance of sustainability to the organisation

G4-2 Description of key impacts, risks and opportunities

Organizational Profile

G4-3 Name of the organization

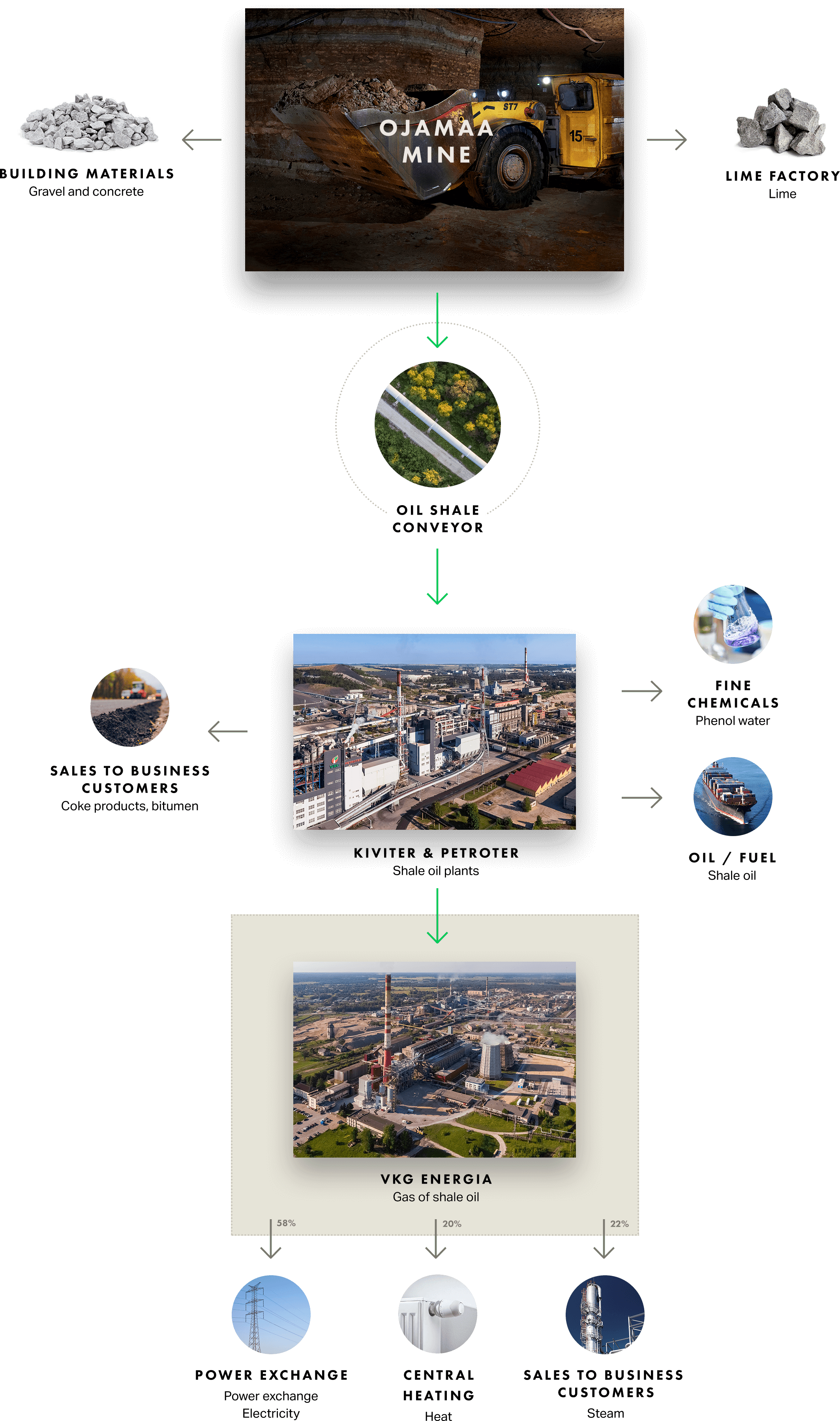

G4-4 Primary brands, products, and/or services.

G4-5 Operational structure of the organization, including main divisions, operating companies, subsidiaries, and joint ventures

G4-6 Number of countries where the organization operates, and names of countries with either major operations or that are specifically relevant to the sustainability issues covered in the report

G4-7 Nature of ownership and legal form.

G4-8 Markets served (including geographic breakdown, sectors served, and types of customers/beneficiaries).

G4-9 Scale of the reporting organization

G4-10 Number of employee

G4-11 Percentage of total employees covered by collective bargaining agreements

G4-12 Organization’s supply chain

G4-13 Significant changes during the reporting period regarding size, structure, or ownership

Commitments to external initiatives

G4-14 Explanation of the effect of any re-statements of information provided in earlier reports, and the reasons for such re-statement

G4-15 Externally developed economic, environmental, and social charters, principles, or other initiatives to which the organization subscribes or endorses

G4-16 Memberships in associations

Identified Material Aspects and Boundaries

G4-17 Entities included in the organization’s consolidated financial statements or equivalent documents

G4-18 Process for defining report content, including determining materiality

G4-19 All aspects identified in the report content

G4-20 Aspects within the organisation

G4-21 Aspects outside the organisation

G4-22 Explanation of whether and how the precautionary approach or principle is addressed by the organization

G4-23 Significant changes from previous reporting periods in the scope, boundary, or measurement methods applied in the report

Stakeholder Engagement

G4-24 List of stakeholder groups engaged by the organization.

G4-25 Basis for identification and selection of stakeholders with whom to engage.

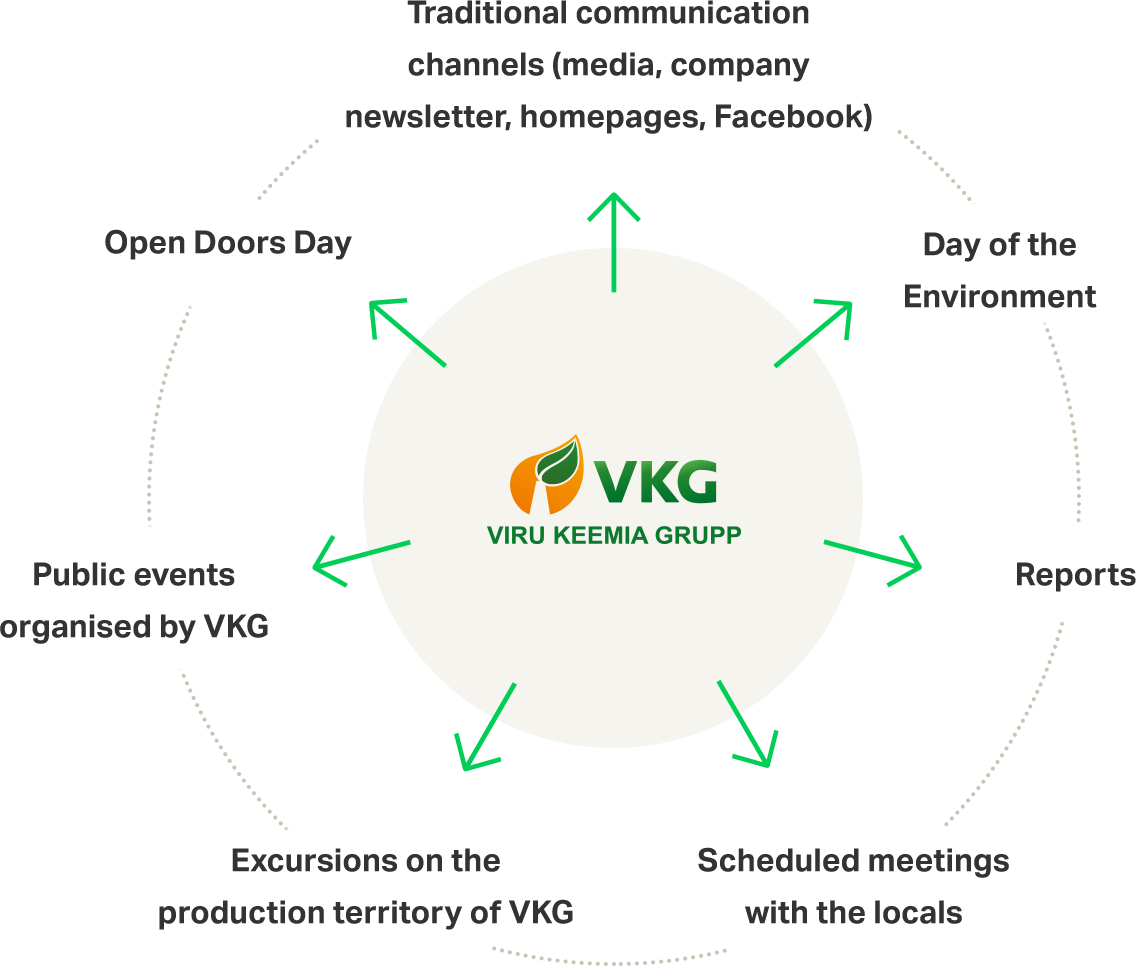

G4-26 Approaches to stakeholder engagement, including frequency of engagement by type and by stakeholder group.

G4-27 Key topics and concerns that have been raised through stakeholder engagement

Report Profile

G4-28 Reporting period (e.g., fiscal/calendar year) for information provided

G4-29 Date of most recent previous report

G4-30 Reporting cycle (annual, biennial, etc)

G4-31 Contact point for questions regarding the report or its contents

GRI content index

G4-32 Report the GRI Content Index for the chosen option

G4-33 Policy and current practice with regard to seeking external assurance for the report

Governance

G4-34 Governance structure of the organization, including committees under the highest governance body responsible for specific tasks, such as setting strategy or organizational oversight

G4-35 Process for delegating authority for economic, environmental and social topics from the highest governance body to senior executives and other employees

G4-36 Appointed an executive-level position or positions with responsibility for economic, environmental and social topics

G4-38 Composition of the highest governance body and its committees

G4-39 Indicate whether the Chair of the highest governance body is also an executive officer

G4-40 The nomination and selection processes for the highest governance body and its committees, and the criteria used for nominating and selecting highest governance body members

G4-41 Processes in place for the highest governance body to ensure conflicts of interest are avoided

G4-42 Role of the members of the highest governance body for guiding the organisation’s strategy on economic, environmental, and social topics

G4-44 Processes for evaluating the highest governance body’s own performance, particularly with respect to economic, environmental, and social performance

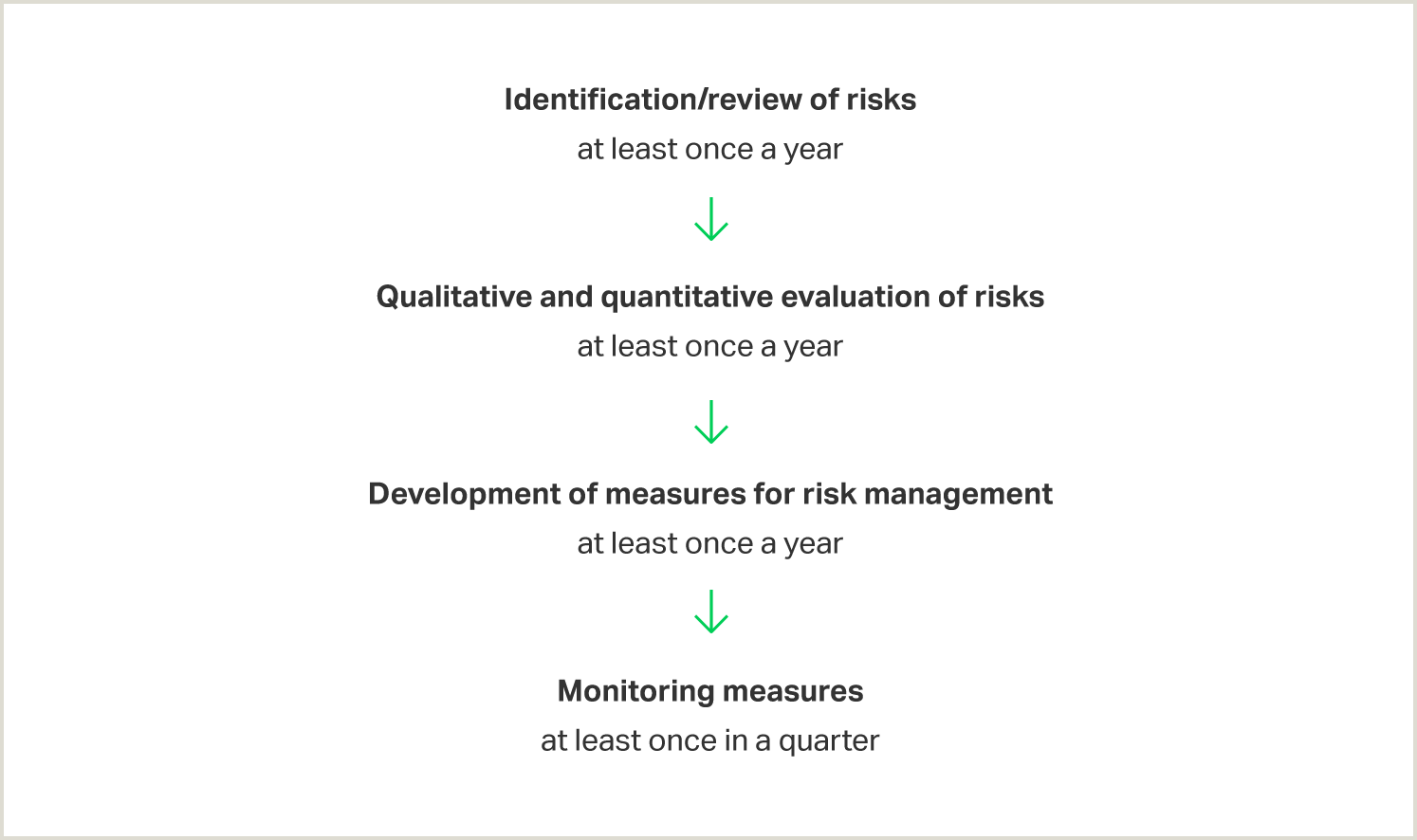

Highest governance body’s role in risk managemenr and performance evaluation

G4-45 The highest governance body’s role in the identification and management of economic, environmental and social impacts, risks, and opportunities

G4-46 The highest governance body’s role in reviewing the effectiveness of the organization’s risk management processes for economic, environmental and social topics

G4-47 The frequency of the highest governance body’s review of economic, environmental and social impacts, risks, and opportunities

Remuneration and incentives

G4-51 Linkage between compensation for members of the highest governance body, senior managers, and executives (including departure arrangements), and the organization’s performance (including social and environmental performance)

Ethics and Integrity

G4-56 Organization’s values, principles, standards and norms of behavior such as codes of conduct and codes of ethics

G4-57 Internal and external mechanisms for seeking advice on ethical and lawful behavior, and mattes related to organizational integrity, such as helplines or advice lines

G4-58 The internal and external mechanisms for reporting concerns about unethical or unlawful behavior, and matters related to organizational integrity

SPECIFIC STANDARD DISCLOSURES

Economic

Aspect: Economic Performance

G4-EC1 Direct economic value generated and distributed

G4-EC2 Financial implications and other risks and opportunities for the organization’s activities due to climate change

G4-EC3 Coverage of the organization’s defined benefit plan obligations - Kontserni töötajate pensionitoetus on ette nähtud kohustusliku riikliku pensionikindlustussüsteemi raames.

G4-EC4 Financial assistance received from government - Aruandeperioodi jooksul on kontsern saanud ühel korral toetuse läbi Keskkonnainvesteeringute Keskuse. VKG Soojus AS, projekt „Jõhvi linna magistraaltorustike renoveerimine“

Aspect: Market Presence

G4-EC5 Ratios of standard entry level wage by gender compared to local minimum wage at significant locations of operation - Viru Keemia Grupi tegevuspiirkonnaks on Ida-Virumaa. Seadusega kehtestatud minimaalne brutopalga alammäär oli 470 eurot kuus.

G4-EC6 Proportion of senior management hired from the local community at significant locations of operation – Not applicable

Aspect: Indirect Economic Impacts

G4-EC7 Development and impact of infrastructure investments and services supported

G4-EC8 Significant indirect economic impacts, including the extent of impacts

Environmental

Aspect: Materials

G4-EN1 Materials used by weight or volume

G4-EN2 Percentage of materials used that are recycled input materials

Aspect: Energy

G4-EN3 Energy consumption within the organization

G4-EN4 Energy consumption outside the organization

G4-EN5 Energy intensity

G4-EN6 Reduction of energy consumption

G4-EN7 Reductions in energy requirements of products and services

Aspect: Water

G4-EN8 Total water withdrawal by source

G4-EN9 Water sources significantly affected by withdrawal of water

G4-EN10 Percentage and total volume of water recycled and reused

Aspect: Biodiversity

G4-EN11 Operational sites owned, leased, managed in, or adjacent to, protected areas and areas of high biodiversity value outside protected areas – Not applicable

G4-EN12 Description of significant impacts of activities, products, and services on biodiversity in protected areas and areas of high biodiversity value outside protected areas – Not applicable

G4-EN13 Habitats protected or restored – Ojamaa kaevanduse piirkonna uurimist ja jälgimist alustati veel enne kaevanduse avamist - aastast 2004 teostatakse pinnavee ja aastast 2005 põhjavee seiret. Lisaks seiratakse 2007. aastast kaevanduse aladel tegutsevate metsiste arvukust ning 2015. aastast ka Muraka soo seisundit.

G4-EN14 Total number of iucn red list species and national conservation list species with habitats in areas affected by operations, by level of extinction risk:

- Animal species of the I category of protection: Flying squirrel Pteromys volans, Sonda extraction field (at present, the company is not operating in this area, i.e. there is no impact)

- Vertebrate animals of the II category of protection: Wood grouse Tetrao urogallus, Ojamaa extraction field (protection zone has been established in its habitat, numeration monitoring has been held)

Aspect: Emissions

G4-EN15 DIRECT GREENHOUSE GAS (GHG) EMISSIONS (SCOPE 1)

G4-EN16 ENERGY INDIRECT GREENHOUSE GAS (GHG) EMISSIONS (SCOPE 2)

G4-EN17 OTHER INDIRECT GREENHOUSE GAS (GHG) EMISSIONS (SCOPE 3)

G4-EN18 GREENHOUSE GAS (GHG) EMISSIONS INTENSITY

G4-EN19 REDUCTION OF GREENHOUSE GAS (GHG) EMISSIONS

G4-EN21 NOX, SOX, AND OTHER SIGNIFICANT AIR EMISSIONS

Aspect: Effluents and Waste

G4-EN22 Total water discharge by quality and destination

G4-EN23 Total weight of waste by type and disposal method

G4-EN24 Total number and volume of significant spills – Not applicable

G4-EN25 Weight of transported, imported, exported, or treated waste deemed hazardous under the terms of the basel convention 2 annex i, ii, iii, and viii, and percentage of transported waste shipped internationally – Not applicable

Aspect: Products and Services

G4-EN27 Extent of impact mitigation of environmental impacts of products and services

Aspect: Compliance

G4-EN29 Monetary value of significant fines and total number of non-monetary sanctions for non-compliance with environmental laws and regulations. VKG Oil AS - sai trahvi tööstusheite seaduse §162 lg 2 alusel summas 8 000 eurot. VKG Kaevandused OÜ – sai trahvi Kiirgusseaduse § 117 lg 2 alusel summas 300 eurot.

Aspect: Transport

G3-EN30 Significant environmental impacts of transporting products and other goods and materials for the organization’s operations, and transporting members of the workforce

Aspect: Overall

G4-EN31 Total environmental protection expenditures and investments by type

Environmental

Labor practices and decent work

Aspect: Employment

G4-LA1 Total number and rates of new employee hires and employee turnover by age group, gender and region

G4-LA2 Benefits provided to full-time employees that are not provided to temporary or parttime employees, by significant locations of operation

Aspect: Occupational Health and Safety

G4-LA6 Type of injury and rates of injury, occupational diseases, lost days, and absenteeism, and total number of work-related fatalities, by region and by gender

G4-LA8 Health and safety topics covered in formal agreements with trade unions

Aspect: Training and Education

G4-LA9 Average hours of training per year per employee by gender, and by employee category

G4-LA10 Programs for skills management and lifelong learning that support the continued employability of employees and assist them in managing career endings

Aspect: Diversity and Equal Opportunity

G4-LA12 Composition of governance bodies and breakdown of employees per employee category according to gender, age group, minority group membership, and ohter indicators of diversity

Society

Aspect: Local Communities

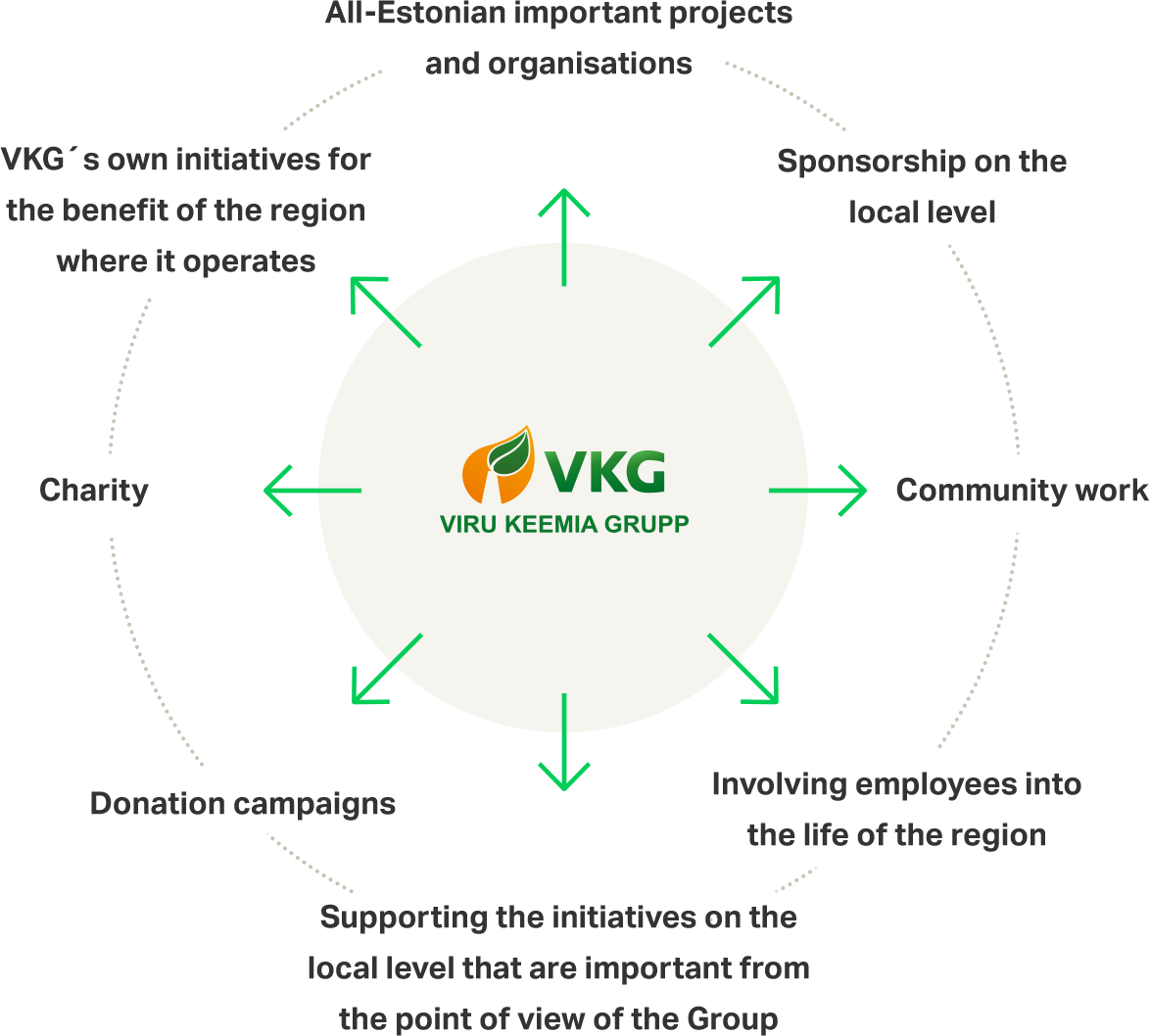

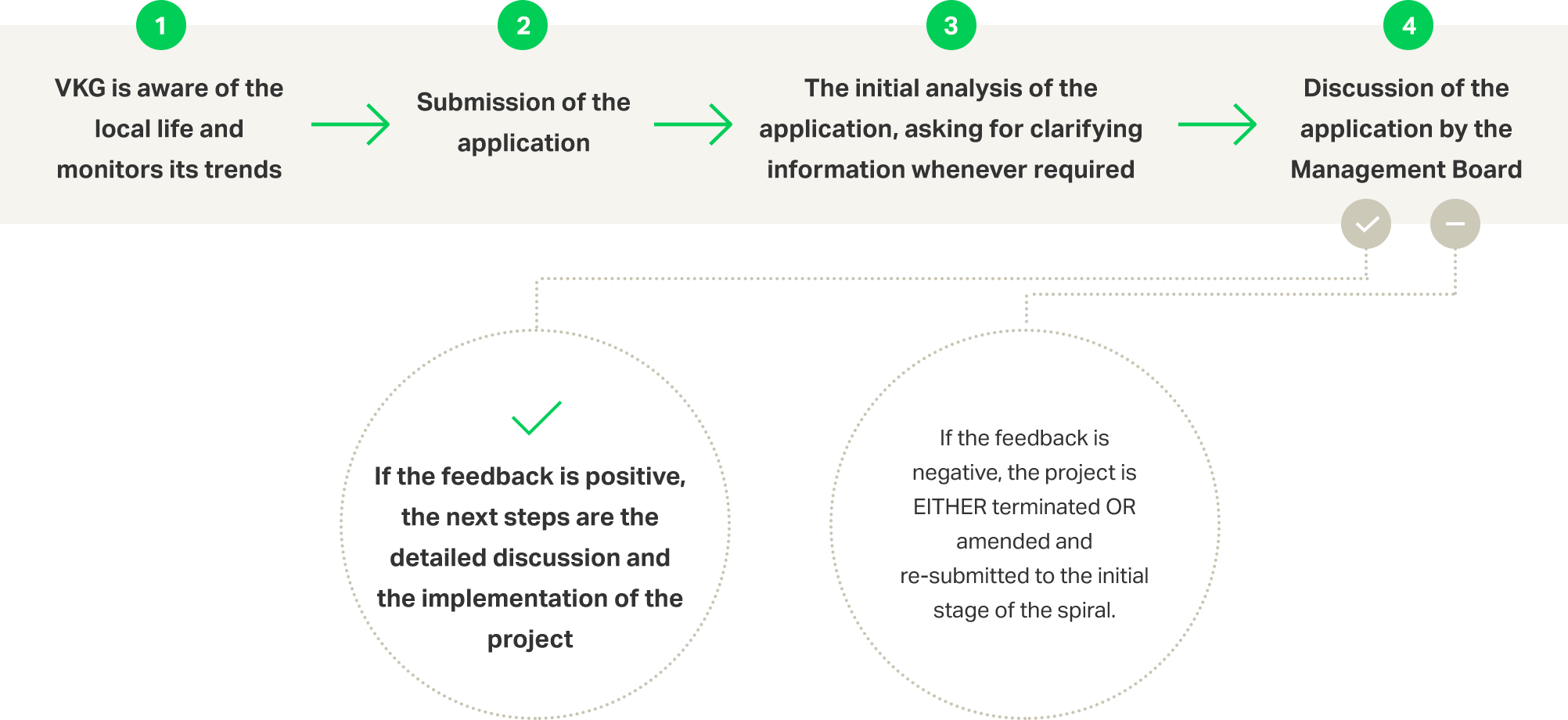

G4-SO1 Percentage of operations with implemented local community engagement, impact assessments, and development programs

Aspect: Anti-corruption

G4-SO5 Confirmed incidents of corruption and actions taken. 2017. aasta juulis fikseeriti kontsernis korruptsioonijuhtum, mille tulemusena peeti kinni kaks kontserni töötajat. Mõlemale isikule esitati kahtlustus korruptsiooni kuriteo toimepanemises altkäemaksu võtmise näol. Kontsern peab korruptsioonikuritegevuse lubamatuks ning suhtub taolistesse õigusvastastesse tegevustesse nulltolerantsusega. Ennetamismeetmetena viidi läbi täiendavad kontrollreidid ning panustati töötajate korruptsioonivastase tegevuse teadlikkuse tõstmisesse selgitustöö ning infomaterjalide jagamise abil.

Aspect: Public Policy

G4-SO6 Total value of political contributions by country and recipient/beneficiary – Not applicable

Aspect: Anti-competitive Behavior

G4-SO7 Total number of legal actions for anti-competitive behavior, anti-trust, and monopoly practices and their outcomes – Not applicable

Aspect: Compliance

G4-SO8 Monetary value of significant fines and total number of non-monetary sanctions for non-compliance with laws and regulations – Not applicable

Product responsibility

Aspect: Customer Health and Safety

G4-PR2 Total number of incidents of non-compliance with regulations and voluntary codes concerning the health and safety impacts of products and services during their life cycle, by type of outcomes – Not applicable

Aspect: Product and Service Labeling

G4-PR3 Type of product and service information required by the organization’s procedures for product and service information and labeling, and percentage of significant product and service categories subject to such information requirements – Information can be found from VKG homepage

G4-PR4 Total number of incidents of non-compliance with regulations and voluntary codes concerning product and service information and labeling, by type of outcomes – Not applicable

Aspect: Marketing Communications

G4-PR6 Sale of banned or disputed products – Not applicable

G4-PR7 Total number of incidents of non-compliance with regulations and voluntary codes concerning marketing communications, including advertising, promotion, and sponsorship, by type of outcomes – Not applicable

Aspect: Customer Privacy

G4-PR8 Total number of substantiated complaints regarding breaches of customer privacy and losses of customer data – Not applicable

Aspect: Compliance

G4-PR9 Monetary value of significant fines for non-compliance with laws and regulations concerning the provision and use of products and services – Not applicable