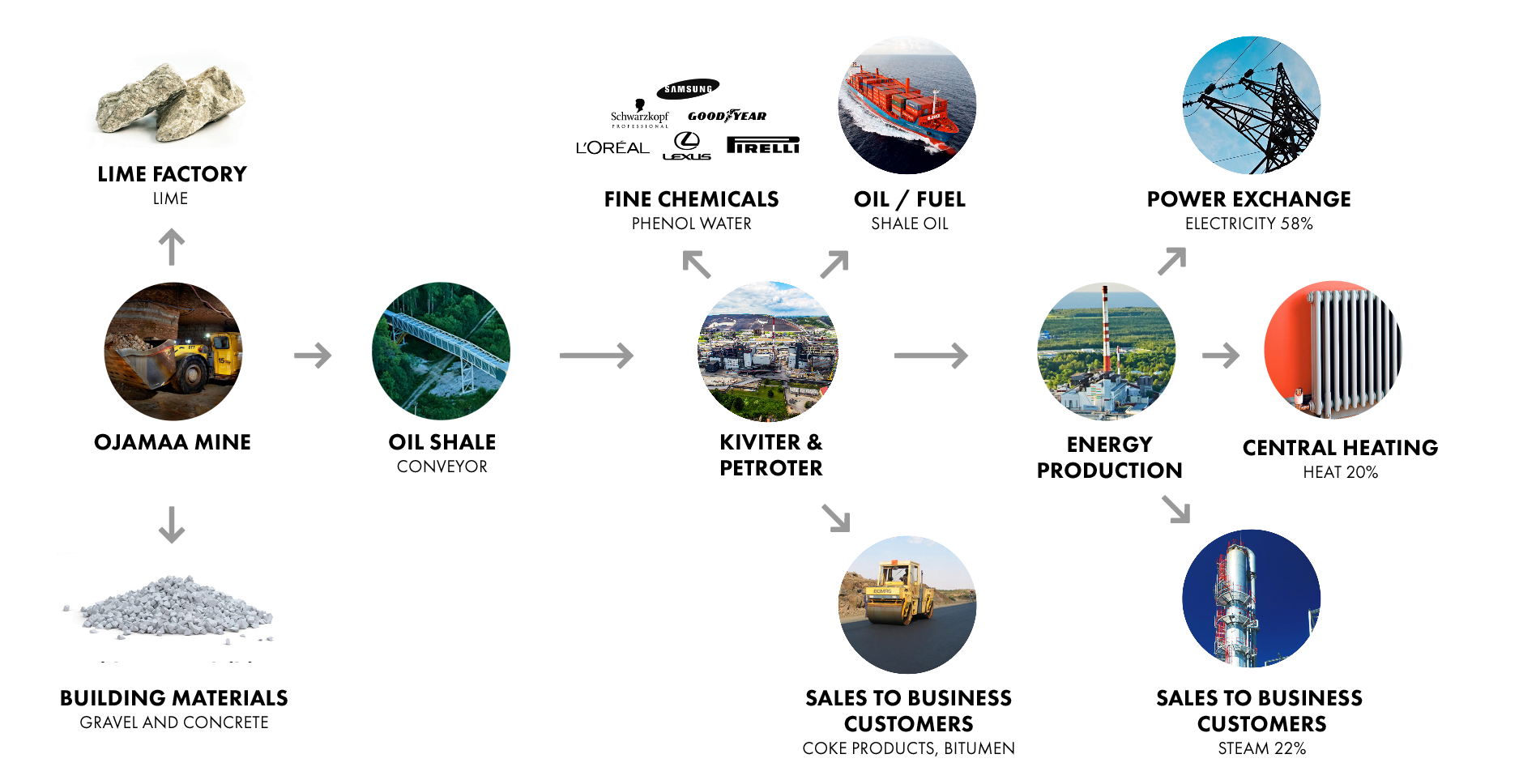

An important step towards the achievement of the goals listed above has been the project of processing of circulation oil, which will help to boost the output capacity, efficiency, and reliability of Petroter oil plants. In addition to the positive trends listed above, the circulation oil project will enable us to enhance the added value of oil shale processing.

One of the challenges in the field of development activities is the provision of oil shale resource both to the plants that process oil shale rock fragments and the ones processing fine oil shale as well as using the existing production capacities in the most efficient way. The management of oil shale production, delivery, and consumption processes must be carried out alongside with the most optimum amount of expenses on logistics and the size of warehouses. The use of conveyor transport within the value chain helps to achieve the goal of reducing expenses on logistics and environmental impact. In 2017, the construction of semi-coke conveyor started in order to transport dangerous waste to the land-fill and reload oil shale from the intermediate storage facility into railway wagons. In addition to a low amount of expenses, the use of conveyor transport improves working environment conditions on the production territory, enhances the efficiency of labour force as well as energy efficiency.

Viru Keemia Grupp is moving in the direction of 4.0 industry, which includes the automation and robotization of production processes. It is clear that it will be hard to remain competitive in the environment of digital industry with old IT and production automation solutions. This is why we are looking for new options for the automation of production and management processes. Viru Keemia Grupp is systematically upgrading the existing IT solutions and implementing new digital solutions related to finance and business management, including the ERP, Business Intelligence (BI) analytics and BigData. The IFS asset management programme is being implemented at the companies of the Group, which helps to enhance the reliability of the equipment, reduce maintenance and repair costs, and ensure good investment decisions.

The solutions for automating industrial processes developed by Viru RMT that are used in everyday operation of Petroter plants, conveyor systems, the operation of fine chemicals and monitoring equipment have enabled us to move in the direction of 4.0 industry. Among the largest clients outside of the Group, Eesti Energia Õlitööstus and Eastman Specialities are definitely worth mentioning.

In connection with changing requirements for the quality of fuel, an important trend is the research of the quality and marketing opportunities of gasoline fractions and shale oil. Proceeding from the expected changes at the market, we are looking for new business opportunities that can be used for enhancing the added value of oil shale products. Such technological solutions as caustic-wash and filtration and distillation, applied in the process of production of gasoline fractions, help to improve the quality of produce significantly. As for shale oils, the goal is to predict the influence related to shale oil marketing, exerted by MARPOL vessel fuel quality requirements at the global sea in 2020.

The changes that have taken place at the global market of fine chemical products show that the production of chemicals is an important development trend with regard to enhancing the added value. The chemical potential of kerogen is constantly worthy of making investments into research and development activities.

We do close cooperation with such educational institutions as Tallinn University of Technology, Virumaa College of Tallinn University of Technology, and Narva College of the University of Tartu. A number of research in the field of oil shale technology, fine chemical products, depositing technologies and environmental research is just a small share of cooperation trends we are following.

An increase in energy efficiency ensures direct connections with heat and electrical systems to new customers. All necessary facilities have been created on the territory of VKG with that purpose in mind: infrastructure, convenient location, safety, connectivity, and heat and power at competitive prices. In 2017, several server farms have seized this opportunity. The immediate vicinity of the power plant enables us to supply server farms with resources that reach tens of megawatt-hours.

We are making contributions into the most innovative development trends, which are based on market demand and future developments. One of such trends is bioenergy and biofuels. We are keeping track of the development process of the new version of the Renewable Energy Directive of the European Union as well the market demand for renewable fuels and the so-called advanced renewable fuels and the formation of the conditions pertaining to raw material.

In the following years, in its development activities, VKG will be focused on the efficiency of production, energy efficiency, quality of products, and ensuring competitiveness. An addition to that, we are contributing into the new developments arising from future development trends, such as fuel, energy and chemical products, as well as the sale of technologies.

Social responsibility and sustainable development

The group analyzes its impact on the environment and society on a regular basis and carefully evaluates the social and environmental impact of new projects. We seek to maintain an active dialogue with all interested parties and to consider their expectations when adopting management decisions. Viru Keemia Grupp’s objectives regarding sustainable development and social responsibility are defined by the group’s mission, strategic principles and priorities, and are a framework of interrelated activities within the integrated strategy of Viru Keemia Grupp. In defining our strategy for sustainable development, we consider global trends and experience in this field.

For Viru Keemia Grupp, entering the path of responsible entrepreneurship has been a conscious and weighted decision, because in our development we have achieved the level, where we wanted to do something more. At present, this concept has been integrated into our DNA. Openness has been an inseparable element in terms of creating the reputation of a reliable and honest company and maintaining it, and it is one of our basic values. We invariably rest against it whenever we discuss some issues or communicate with the public.

Eight years ago we decided that the topics of social responsibility and sustainable development deserve much more than one chapter in our Yearbooks. Hence since 2010 we have been publishing all of our environmental, social, and economic data in the Social Responsibility and Sustainable Development Report, which is drawn up in accordance with the principles and requirements of the internationally acknowledged Global Reporting Initiative (GRI). In our reports, we do not only write about success stories, but also deal with problems and challenges our company is facing as well as their solutions, publish environmental indicators, provide an overview of planned activities and accompanying effects. Besides, by publishing such a detailed report we wish to familiarise and promote the concept of sustainable development in Ida-Viru County and Estonia as a whole, since we have a strong belief that responsible activities guarantee the sustainability of the company, the society, and the state.

DIRECTIONS OF VKG’S SOCIAL RESPONSIBILITY AND SUSTAINABLE DEVELOPMENT POLICY

VKG’s environmental protection policy was introduced in 2001. In our acitivities, we are guided by the goal to demonstrate that a large industry can also be responsible, eco-efficient and use resources with maximum efficiency. The group’s largest investments are directed at environmental activities and are one of the countries largest in this field. Over the years, VKG has invested around 100 million euros in environmental protection projects. We have planned more than 50 million euros of environmental investments for the years 2015-2020.

OPENNESS AND TRANSPARENCY

Social reporting means total disclosure of data on social, economic and environmental impacts in accordance with the Global Reporting Initiative (GRI).

PRINCIPLE OF RESPONSIBILITY

Socially responsible production organization both in the company itself (creation of safe working conditions, motivation of employees, additional benefits, additional payments, constant dialogue between employees and employers) and among employees (everyone is responsible for everything).

HONESTY AND CORRECTNESS

Public relations standards have been approved by the company that prohibits the submission of incorrect or inaccurate data.

PROMOTING LOCAL LIFE

Our priority is to support Virumaa, the socially beneficial activities of organisations, people and societies that operate here. The group pays particular attention to the development of the region, maintaining close liaison with local authorities and residents. VKG supports athletic, cultural and educational initiatives and contributes to the promotion of local life through the voluntary work of its employees.

We understand that cooperation with interested parties is a major responsibility. We seek to implement responsible approach in the course of cooperation while developing our activities and considering the interests of all parties. An open dialogue with interested parties creates conditions for increasing the efficiency of business activity, provides opportunities to achieve better results, and works for strengthening the group’s brand. Cooperation also allows the development of activities in the areas of product safety and environmental protection with maximum efficiency.

Through continuous cooperation, it is possible to coordinate and more clearly focus our efforts on achieving common goals in the field of sustainable development. As a large and efficient group, Viru Keemia Grupp seeks to be the leader and initiator of positive change.

The group considers its main interested parties to be those whose interests are most closely related to the group’s activities and those who, in turn, have the greatest impact on the group’s ability to fulfil its strategic objectives.

We understand that our activity in the area of sustainable development extends beyond our organisation or supply chain, creating an example of a socially responsible and ethical behavior of a major participant in the market.

In the Group, it has become a tradition to hold meetings with the representatives of the local community, in the course of which people are familiarised with development trends, and environmental issues are discussed. Besides, traditional Open Door Days are held regularly, within the frames of which all people can visit the production territory and see with their own eyes how everyday processes are organised at the large modern industrial company. The doors of our production facilities are also open to school and university students, who are provided with an opportunity to pay study visits and have tours around the territory of the company.

COMPLIANCE WITH INTERNATIONAL STANDARDS

Implementation of the principles of social responsibility approved by international organizations (GRI, UN Global Compact) in the company.

Throughout the years, over 1 mln of EUR has been invested into the promotion of sport, science, and culture in the area.

The largest education projects in 2017

Jõhvi Gymnasium and Viru Keemia Grupp have entered into the cooperation agreement for continuing the STEM elective course

In 2016/2017, within the frames of cooperation between Jõhvi Gymnasium and three large production companies in the area, namely VKG, Eesti Energia, and Eastman, the new elective course was developed for the students of the 11th grade of Jõhvi Gymnaisum, i.e. the STEM course. The STEM course is a subject that incorporates four areas, i.e. Science, Technology, Engineering, and Mathematics, into a single sustainable whole, in which natural and exact sciences get linked to vital everyday problems, and students are provided with basic knowledge in the field, which they are interested in, have potential for further studies, and a chance to choose future profession. Within the frames of the STEM course, study visits and lectures have taken place in the companies of the Group. For example, pupils have visited VKG Energia, where they familiarised themselves with the processes of production of heat and electricity and obtained an overview of trends in the field of energy engineering. Pupils learned a lot about the environmental footprint and other environmental issues during a study visit to Ojamaa mine. Since this course is very popular and necessary, the STEM course will also be provided in the academic year 2018/2019, with the assistance of VKG.We are going to continue awarding scholarships to the best students of Tallinn University of Technology

In 2017, we awarded a total of 6,700 EUR of scholarships via the Development Fund of Tallinn University of Technology. VKG awards scholarships twice a year.VKG community projects

Supporting the most talented gymnasium students in the area

The Competition of Five Schools, in which traditionally the best gymnasium students of the Republic show their knowledge in Mathematics, Chemistry, and Physics, has already been held for over half a century. Six years ago this elite club, which incorporates five strongest gymnasiums in Estonia with the in-depth study of sciences, opened its doors to the teams from Ida-Viru County. The participation of the local team in such a reputable contest has been a good initiative of the Group, and we are going to continue providing this kind of support in the future, too. The main thing is that we could have motivated pupils who are interested in sciences and see their future as being connected with technical education. We are convinced that our task is to help the youth in their studies and provide them with an opportunity to show what they are capable of.We are bringing the best ballet performances to the inhabitants of Ida-Viru County

Jõhvi Ballet Festival can be referred to as the main cultural event in the area. But, in addition to that, it has so far been the only ballet festival in Estonia, which has built up a fantastic reputation abroad as well. The fact that this festival is held in Ida-Viru County provides us, the inhabitants of Ida-Virumaa, with the chance to enjoy unique and world-known ballet performances close to our homes. VKG is pleased to be a partner of this event. Successful cooperation between the Group and Jõhvi Concert Hall, which is the organiser of the festival, has been going on for many years. Within the frames of the Ballet Festival in 2017, we supported young dancers that are just in the beginning of their ballet path, so that future talents could also gain some experience of performing on the big stage and show their skills to the wider audience.Donors’ Day

Another long-term tradition of the Group is the Donors’ Day. The enjoyable cooperation between VKG and the blood bank of Ida-Viru Central Hospital has been going on for many years. There are many long-term donors in the Group, and new volunteers keep on joining in every year. Within the past year, over 30 litres of blood was donated by the employees of the Group.Acknowledgement

Viru Keemia Grupp has been acknowledged as a responsible company. In 2017, the group was awarded bronze level acknowledgement for the eighth consecutive year.

We have been awarded with the bronze level acknowledgement for the results the Group managed to achieve in the field of responsible entrepreneurship in 2016. Last year we were forced to face with a serious oil crisis and make difficult decisions. Regardless of that, we are still acting as a responsible company and have managed to preserve our values. It means that our bronze level acknowledgement is actually worth being gold. At the same time I believe that VKG has got power and will to move on to the next level – silver level acknowledgement! We can achieve any goals we set while we are doing it together.

Ahti Asmann, the Chairman of the Board of the Group

Responsible Estonian Business

2010, 2011, 2012, 2013, 2014, 2015, 2016, 2017

Estonian Culture-Friendly Business

2012, 2013, 2014

The implementation of a unified social responsibility and sustainability policy at VKG ensures its contribution into the enhancement of the competitiveness of the Estonian economy and facilitates the social and economic development of Virumaa. The main principles and activities of VKG in the field of sustainability and responsible entrepreneurship are described in detail in Social Responsibility and Sustainable Development Report.

Environmental activity Forward

Our people