For a cleaner environment

In shaping its environmental policy, VKG places great value on social responsibility and understands that environmental impact management is a prerequisite to sustainable development.

We have created an integral and systemic approach to environmental issues, which is in accordance with European Union and Estonian legal acts as well as the environmental requirements arising from the Best Available Technology (BAT) framework documents. All VKG’s production units are in conformity with environmental requirements, but we are still constantly looking for ways to optimise processes and reduce the production footprint. We aim to fully use the potential of oil shale in line with the principles of the circular economy with as small a footprint as possible.

The Group implements technologies for the protection of the environment and for the rational use of resources and promotes a culture of environmental safety. We strive to reduce risks related to the environment and make significant contributions to nature conservation programmes.

Main areas of work

- development and implementation of environmentally friendly technologies,

- implementation of nature protection programmes,

- management of a warning and accident localisation system,

- environmental monitoring and supervision over the environmental friendliness of production,

- risk management in the area of environmental safety,

- introduction and development of a culture of environmental safety.

In order to consistently reduce the environmental impact, the Group runs an environmentally friendly management system that meets the requirements of international standard ISO 14001:2015.

Our environmental protection objective is to reduce the shale oil production footprint and environmental impact through the effective valuation of oil shale as a resource and the implementation of the best possible technologies.

VKG’s guiding environmental principles:

Acting upon an environmental management system conforming to the international standard ISO 14001.

In our everyday activities, we follow the requirements prescribed in legal acts, conventions and agreements of Estonia and the European Union.

We identify the environmental impact of our production activities and assess its conformity with legal acts and other requirements.

We consider it important to inform the region’s institutions and population about the enterprise’s activities and possible environmental impacts of those activities.

We pay much attention to promoting sustainable development in the enterprise, reusing as many materials and wastes generated from the production process as possible.

We consider it important to have good cooperation with research and development institutions, both for solving environmental issues and for developing new technologies.

We encourage our employees to improve their knowledge about the environment protection and we recognise and encourage practical use of that knowledge.

We work towards unlocking the full potential of oil shale, creating additional value with our oil shale products.

Our environmental activities are more than before focused on the European green Deal and the related restriction of greenhouse gas emissions. In the light of the renewed EU climate policy, VKG is analysing investment possibilities to expand production activities into new areas in order to support the orientation towards climate neutrality. We also continue investments into increasing the efficiency of production processes and seek new possibilities to optimise processes and thereby reduce environmental impact.

Strategic vision of reducing the impact of industry

The main focus of environmental activities is on reducing ambient air emissions, particularly with regard to sulphur compounds and emissions which cause unpleasant odours. We pay a lot of attention to increasing the energy efficiency of the entire production chain and finding ways to reuse waste.

Our environmental goals are as follows:

- It is important for the Group to apply the principle of a circular economy, which ensures the most efficient use of resources,

- We reduce sources of pollution which cause unpleasant odours,

- We minimise the effects related to extraction and find additional possibilities for the maximum recycling of oil shale waste rock,

- We develop the best available techniques (BAT) for oil shale processing and lengthen the existing production chain to the maximum extent possible.

The following environmental studies were conducted in 2020 and 2021:

- Verifying the CO2 emission quantities generated at the Group and upgrading the monitoring system,

- Monitoring groundwater and surface water at the Ojamaa Mine,

- Monitoring groundwater at the ash storage site at the Ahtme thermal power plant,

- Creating a hydrological model of the Oandu Mine and assessing the environmental impact,

- Developing acoustic monitoring methods for wood grouse and performing the monitoring.

VKG strives to operate in a way that does not harm the environment or people's health and is concerned about the preservation of its production resources. Safety is one of the three strategic priorities of the group. We are consistently moving towards achieving the main goals of ecology and production safety - 0 fatalities and 0 technical accidents.

We continued the implementation of the plan for reducing the occurrence of odoriferous substances in 2020, performed the last measurements of the level of odoriferous substances in order to assess the results of the measures taken, and conducted an inventory of emission sources. In 2021, an extensive reconstruction project of the Petroter I oil production plant commenced, as a result of which VKG’s impact on the quality of atmospheric air in Kohtla-Järve and its vicinity will be significantly reduced in 2022. In 2021, VKG Oil invested into reducing emissions from the breather systems of the Petroter I-II tanks and phenol water treatment equipment tanks, which means a reduction of the emission of air-borne organic compounds by up to 3.4 tonnes a year.

During the reporting period, the assessment of the environmental impact of the Oandu Mine continued on the basis of VKG Kaevandused’s application.

On 30 October 2020, the Group’s subsidiary VKG Kaevandused submitted an application to the Environmental Board for the extension of the Ojamaa Mine (environmental permit KMIN-055). The requested extension is located in the Aidu and Kohtla mining fields and in the Ojamaa exploration field, whereas impact assessments for the Aido and Ojamaa fields have already been performed. The area of the mining claim would increase by 279.16 ha and the active proved reserves of oil shale related to the mining claim would grow by 10,091,000 tonnes, whereas the relatively small reserves located between the oil shale mines would be probably left unused after the closure of the Ojamaa Mine. The extension would allow us to replace the oil shale reserves which we have had to exclude from actives reserves in the currently mined mining claim due to extraction conditions. On 22 April 2021, the Environmental Board initiated the assessment of environmental impact for the application.

On 9 April 2021, the Environmental Board initiated an environmental impact assessment for the amendment of Uus-Kiviõöi II mining permit No. MK/333343 on the basis of VKG Kaevandused’s application. The actions applied for were to increase the allowed maximum annual limit of the Uus-Kiviõli and Uus-Kiviõli II mines jointly developed by Enefit Power AS and VKG Kaevandused (to 10 and 15 million tonnes, respectively) and to allow mineral transport from the mines to the Ojamaa industrial complex.

In 2020, the European Commission approved VKG Oil’s application for the allocation of additional free quota for the Petroter facility. The application was based on technological changes made in the production process as a result of which production efficiency increased by over 15%.

Carbon dioxide emissions and the free quota have a significant effect on the Group’s economic activities. Activities related to the development of the framework of the trading system of the 4th greenhouse gas trading period of the European Union started in 2019. The Group presented its input concerning the functioning of the system to the European Commission and submitted applications concerning its facilities. In 2020, the European Commission reviewed the applications of VKG Oili, VKG Energia and VKG Soojus for the allocation of free quota for the period of 2021–2025. The said applications were approved at the beginning of 2021.

The Environmental Board issued VKG Oil waste registration No. RE.JÄ/513406 for conducting a greenery experiment with waste water compost at a hazardous waste landfill. The experiment is necessary in order to determine whether the compost can be used for planting greenery on the slopes upon the closure of the landfill. The first stage of the experiment commenced in October 2021 and the activities continue in 2022.

Environmental Footprint

Our activities as a production company are strictly regulated. All our production activities have passed the environmental impact assessment process and received a respective environmental permit. The company has a full overview of its environmental footprint. The environmental area is also included in the quality management system. For the purpose of providing a better assessment of the environmental effect of the life cycle of products and production activities, a programme of assessment of the environmental footprint was launched in the Group in 2018. The implementation of the new method enables us to understand the environmental effect of different stages of the production and consumption of products, compare the footprint with other similar products on the market, and reduce the environmental effect of the products by means of a life cycle analysis.

The environmental footprint part of VKG Kaevandused was completed in 2019. VKG’s production units work using the best available technology, which means that the use of the technology ensures the minimal environmental impact. All the products sold by the Group are equipped with safety sheets which provide all the main specifications, the identification of hazards, handling and storing, transport information, ecological information, legal acts that regulate waste management, etc. VKG production units apply various degrees of environmental monitoring. For instance, atmospheric air in Kohtla-Järve is monitored with a monitoring station which measures the concentration of hydrogen sulphide (H2S) and sulphur dioxide (SO2) with the precision of a minute, as well as wind direction and speed. The data are public and available to all interested parties at any time on the webpage www.ohuseire.ee. The wind direction is used for assessing which production unit may be the cause of increased levels of pollutants. In addition, the situation is also analysed using portable measurement devices with which it is possible to identify the main pollutants that cause odoriferous disturbances (H2S and air-borne organic compounds).

Management of climate impacts

The Group continues to invest in development activities aimed at reducing carbon emissions, seeking possibilities to reduce the environmental footprint of shale oil production. In the light of the renewed climate policy goals, VKG is analysing investment possibilities to expand production activities into new areas in order to support orientation towards climate neutrality.

Reducing environmental impact

KThe Group’s production units have valid environmental permits and we comply with the requirements thereof. However, we always approach our environmental activities on a broader basis – we strive to do more than prescribed by law.

We have established the following objectives for ourselves:

- Initiating projects aimed at reducing CO2 emissions;

- Applying the principle of a circular economy which ensure a more efficient use of resources;

- Reducing the number of pollutant sources that cause unpleasant odours;

- Minimising the effects related to mining (including optimising the use of water) reusing waste rock;

- Developing the BAT of oil shale processing and extending the existing the existing production chain to the maximum extent.

With regard to all these parameters, we keep a close eye on statistics (including our own monitoring systems) and prepare overviews on an ongoing basis. In order to achieve objectives, we prepared activity plans on the basis of which investments are made. At the same time, the Group has a number of activities aimed at monitoring the diversity of nature (the results of which can be taken into account in decision-making, if necessary). The exploration and monitoring of the region of the Ojamaa Mine started even before the mine was opened: surface water is monitored since 2004 and groundwater since 2005. In addition, the number of wood grouse active in the area of the mine is monitored since 2007 and the condition of the Muraka swamp since 2015. In 2020, a new wood grouse monitoring methods plan was developed upon the order of VKG Kaevandused. That was approved by the Environmental Board at the beginning of 2021. The monitoring (specimen count) of the Ojamaa wood grouse is now performed under national monitoring. Groundwater and surface water monitoring also commenced in 2021 in the area of the yet not opened Uus-Kiviõli II Mine.

Management system

The majority of the subsidiaries of Viru Keemia Grupp AS comply with the international ISO standards:

VKG Oil

VKG Oil holds environmental and quality management system certificates ISO 14001 and ISO 9001 since 2006, and has also implemented occupational health and safety management system ISO45001 and, since 2019, energy management system ISO 50001.VKG Energia

VKG Energia has implemented occupational health and safety management system ISO45001 and, since 2013, environmental and quality management system ISO 14001 and ISO 9001, as well as energy management system ISO 50001.VKG Kaevandused

VKG Kaevandused applies environmental and quality management system ISO 14001 and ISO 9001 and occupational health and safety management system ISO 45001.VKG Soojus

VKG Soojus has implemented environmental and quality management system ISO 14001 and ISO 9001 and occupational health and safety management system ISO45001.Viru RMT

Viru RMT has implemented quality system ISO 9001.VKG Elektrivõrgud

VKG Elektrivõrgud has implemented quality management system ISO 9001 and occupational health and safety management system ISO 45001.VKG Logistika

VKG Logistika has implemented environmental and quality management system ISO 14001 and ISO 9001 and occupational health and safety management system ISO 45001.Investments into

environmental protection, and environmental charges

VKG is an enterprise of significant impact and pays environmental charges for the use of the environment and for emissions. Figure 1 shows the changes in the amount of the Group’s environmental charges: it grew significantly from 2010 and dropped from 2015 due to the economic standing of the enterprise, and has then gradually recovered since 2017.

In 2020, VKG’s environmental charges amount to nearly 8.3 million euros. Compared to previous years, we paid fewer pollution charges for two reasons. Firstly, pursuant to regulation of the Minister of the Environment, “The procedure for classification of waste and the list of waste”, oil shale ash is no longer classified as hazardous waste as of 1 January 2020. The change was inspired by a study commissioned by the Ministry of the Environment, which found that oil shale ashes should no longer be classified as hazardous waste, but should be treated as ordinary waste. In connection with that, the oil shale ash disposal charge was temporarily reduced in 2020.

Secondly, the resource charge payable for the extraction of oil shale was lower in 2020 than in previous years.

Pursuant to regulation “The rates for state-owned mineral resource extraction charge” adopted by the Government of the Republic on 7 July 2016, the oil shale extraction charge is determined for every three-month period (reporting quarter) on the basis of the average world market price of 1% sulphur content heavy fuel oil applicable during that period, which remained low in 2020. The quantity of oil shale extracted in 2020 was also smaller than in previous years, because the Ojamaa Mine was forced to temporarily reduce production due to the wide spread of COVID-19.

In 2021, the amount of environmental charges took a leap upwards, as the oil shale ash disposal charge increased to the 2019 level and an increase in the world market price of 1% sulphur content heavy fuel oil caused the resource charge on the extracted oil shale to grow.

THE GROUP’S ENVIRONMENTAL CHARGES (MILLION EUROS, EXCLUSIVE OF THE COSTS OF CAPTURE DEVICES, ENVIRONMENTAL MONITORING, ENVIRONMENTAL STUDIES AND OTHER SUCH)

Viru Keemia Grupp invests in the minimisation of the environmental impact and constantly works towards improved efficiency. The aim is to increase the value of oil shale to the maximum, i.e. to fully use up the potential of the resource. From the perspective of the environment, that means a smaller environmental impact per one unit of processed oil shale and greater social and economic benefit. In order to ensure the sustainability of shale oil production, we need to invest into environmental protection and the development of the best possible technologies, take part in the development of legal acts, perform production and environmental monitoring, optimise production, and implement energy-efficient solutions. The legal acts of the European Union and the Republic of Estonia as well as the increasing production needs establish ever greater requirements and new higher environmental goals for the Group enterprises.

VKG divides investments into environmental protection into two:

1.

investments that reduce the

impact on the environment directly

2.

investments that reduce the

impact on the environment indirectly

Investments that directly reduce the environmental impact include investments that provide immediate reduction of environmental impact. They include, for instance, the so-called end-of-pipe investments (trapping equipment), the renovation of tank fleets, investments related to closing or reducing the existing sources of pollution, investments related to the treatment of waste, etc.

Investments that indirectly reduce the environmental impact include activities which reduce the environmental impact in the course of long-term consistent activities. This includes, for instance, investments into BAT, and the development and application of new more efficient technologies that save natural resources.

Investments have decreased in recent years, as the political changes arising from the European Union climate goals (particularly in the GHG Emission Trading System) caused a lot of uncertainty. It was difficult for the Group to forecast the coming changes and plan investments.

In 2020, investments into environmental projects and the improvement of reliability and efficiency amounted to 5.2 million euros, of which direct investments into the reduction of environmental impact formed 0.8 million euros. The volume of environmental investments increased in 2021 and reached the top level of the past five years.

INVESTMENTS THAT DIRECTLY AND INDIRECTLY REDUCE THE ENVIRONMENTAL IMPACT (million euros)

- Directly

- Indirectly

In 2017–2020, VKG’s direct investments have mainly been aimed at measures to reduce odoriferous substances. Nuisance and Pollutant Emissions in the Järve District of the City of Kohtla-Järve’, a study commissioned by the Estonian Environmental Inspectorate and carried out by the Estonian Environmental Research Centre, on the basis of which VKG Oil commissioned additional measurements and the modelling of odoriferous substances in its production territory. On the basis of the obtained results, the enterprise prepared a new action plan for reducing odoriferous substances, foreseeing activities in the extent of approximately 1.1 million euros in total. In 2020, we continued with the programme for reducing odoriferous substances launched in 2018, performing measurements of the levels of odoriferous substances in order to assess the results of the measures taken and conducting an inventory of the sources of emission of odoriferous substances.

In 2020, we carried out a cooler project in the framework of which we installed three coolers on the piping of the semi-coke generated in the process of oil production and two coolers on the distillation equipment at VKG Oil. As a result of this, the Group’s annual CO2 emissions decreased by nearly 12,000 tonnes. Important investments were also made in the renovation of heating mainlines and the humidification system of the hazardous waste landfill as well as in increasing the work efficiency of the flue gas desulphurisation devices at the Põhja Thermal Power Plant.

In 2021, investments included the reconstruction of the Petroter I shale oil plant, the maintenance of the desulphurisation complex (including the lime factory) of the Põhja Thermal Power Plant, the monitoring of surface water and groundwater and the environmental projects of the mines.

VKG’s first shale oil plant operating on the basis of the Petroter technology was launched in 2009. During its time of operation, the Petroter I plant has processed 10 million tonnes of oil shale and produced more than 1 million tonnes of shale oil. In 2021, active preparations started for a large-scale reconstruction of the PetroterI plant and reconstruction works started in June 2022.

The repairs are expected to take approximately five months. During that time, a considerable part of the amortised equipment is replaced, which will reduce the probability of emergency shutdowns due to equipment failure as well as repair costs. The reconstruction of the plant will also increase the oil shale processing capacity from 140 tonnes to 160 tonnes per hour and the modernisation of the reactor will also increase the yield of shale oil obtained from one tonnes of oil shale.

The most important and large-scale change, however, was the replacement of the recovery boiler responsible for the purification of flue gases. After 11 years of operation, the recovery boiler was not operating as efficiently as it should. As a result of the replacement, the environmental impact of flue gases will be reduced and the residual heat of flue gases can be used for producing steam and hot water.

The renovation investment under the Group’s programme for reducing odour disturbances is over 24 million euros and will have a positive effect on the air quality of the city.

Emissions to air

Carbon dioxide (CO2) emissions

CO2 emissions have been on a downward trend in 2019–2021, mainly in connection with production capacity. The Group is constantly looking for technically feasible and economically justified solutions for reducing greenhouse gas emissions.

THE GROUP’S CO2 EMISSIONS ACROSS COMPANIES (TONNES)

- VKG Energia

- Oil Kiviter

- Oil Petroter

- VKG Soojus

Sulphur dioxide (SO2) emissions

Compared to previous years, VKG Oil’s SO2 specific emissions remained stable in 2020 and 2021 and VKG Energia’s specific emissions decreased.

VKG OIL AND VKG ENERGIA SULFUR DIOXIDE EMISSIONS PER PRODUCTION

(TON/TON)

- VKG Oil

- VKG Energia

Ambient air pollution charge

Until 2015, there was an upward trend in ambient air pollution charges, caused mainly by an increase in pollution charge rates as well as in production volumes. In 2016, the air pollution charge amounted to 0.64 million euros, which was 3.2 times less than the amount paid in 2015. This was thanks to the reduction of SO2 emissions achieved by the launch of a new desulphurisation system at the Põhja Thermal Power Plant of VKG Energia. Also, the Lõuna Thermal Power Plant, a considerable source of SO2, was closed. An amendment to the Environmental Charges Act also had an effect. Since 2016, the ambient air pollution charges have been largely on the same level, being linked to production volumes.

Ambient air pollution charges (EUR)

Water usage and waste water

The main objectives in the area of water usage include the expedient use of water resources, the efficient purification of waste water and the prevention of the entry of shale oil into natural water bodies. Viru Keemia Grupp performs supervision over water conservation areas, surface water, groundwater and waste water and evaluates the deposition of surface water objects in its area of activity.

Water usage

There were no significant changes in the Group’s water usage in 2020–2021, fluctuations are related to production levels.

WATER USAGE AT THE GROUP (m3)

- Lake water

- Groundwater

- Mining water in an enrichment plant

Water emissions

In 2020 and 2021, the Group’s water emissions remained at the same level as in 2019, being mostly related to the surface area of mines, the amount of precipitation, and production levels.

WATER USAGE IN THE GROUP (m3)

- Wastewater

- Rainwater

- Wastewater from a mine (settling basin)

Water pollution charges

In 2020 and 2021, the Group’s water pollution charges remained at the same level as in 2019, being mostly related to the surface area of mines, the amount of precipitation, and production levels.

CHARGE FOR THE EXCLUSIVE RIGHT OF USE OF WATER, AND WASTE WATER CHARGE (EUR)

- VKG Energia

- VKG Oil

- VKG Kaevandused

- VKG Soojus

Industrial waste

Constantly checking the reliability of equipment and introducing new technologies allow us to minimise the risk of soil contamination. The Group also actively reuses production waste.

Hazardous and non-hazardous waste and reuse

In 2017, a new type of waste was added to VKG’s waste list – waste from gas cleaning containing hazardous substances (waste code 10 01 18*). Waste generated in the desulphurisation process is classified under this code. Thus, the main type of waste at VKG’s Põhja Thermal Power Plant is the gas purification waste which is generated as a result of the desulphurisation process and contains hazardous substances. VKG Oil’s production processes generate semi-coke and oil shale ash. In 2019, the Department of Energy Technology of TalTech and the Geology Department of the University of Tartu conducted a study of the harmfulness of oil shale ashes and determined that oil shale ash is not hazardous waste. Pursuant to a decision passed in 2019, oil shale ash is no longer included in the list of hazardous waste. In 2020 and 2021, the amount of semi-coke generated was smaller than in the previous two years, as Kiviter’s 1,000-tonne gas generation plant unit was shut down.

THE AMOUNTS OF THE MAIN TYPES OF HAZARDOUS WASTE IN THE VKG

| 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | 2021 | ||

|---|---|---|---|---|---|---|---|---|

| Semi-coke | 0,62 | 0,23 | 0,63 | 0,73 | 0,79 | 0,66 | 0,65 | |

| Gas purification waste | 0 | 0 | 0,05 | 0,06 | 0,06 | 0,06 | 0,06 | |

| Total hazardous waste (million tonnes) | 0,62 | 0,23 | 0,68 | 0,79 | 0,85 | 0,72 | 0,71 |

Semi-coke and oil shale ash are the main types of waste generated in the shale oil production process. The former is generated in equipment using the Kiviter technology and the latter in equipment using the Petroter technology.

The ratio of semi-coke generated per one tonne of production to the total amount of ash has decreased compared to 2016 and has remained stable in the past five years. Over the past six years, the proportion of the Petroter technology in the production of shale oil has increased, which means that more low calorific value fine oil shale is processed and the oil output indicators are lowed compared to the Kiviter technology. At the same time, VKG Oil has implemented various technological innovations that have improved the efficiency of the plant (including adding a circulation oil purification device, coolers for capturing gas condensate from flue gases) and reduced the generation of waste.

GENERATION OF WASTE PER PRODUCT UNIT AT VKG OIL

(TON/TON)

The Group’s waste generation is presented in the table below. Of the non-hazardous waste generated, the following types of waste are mainly reused:

- waste rock, which is sold as filler material and reused,

- scrap metal, which is recycled.

VKG Kaevandused reuses the majority of the annual wate rock quantity and no waste rock is deposited. In 2020 and 2021, more than a half of the generated waste rock was reused in the framework of the project of refurbishing the Aidu quarry. Waste rock was also recirculated as a certified product called „Ojamaa Mine limestone filler material”.

GENERATION AND REUSE OF NON-HAZARDOUS WASTE IN THE GROUP (TONNES)

| 2017 | 2018 | 2019 | 2020 | 2021 | ||

|---|---|---|---|---|---|---|

| Construction and demolition waste | 459 | 513 | 630 | 320 | 222 | |

| Common waste | 284 | 283 | 286 | 166 | 125 | |

| Scrap metal | 763 | 3 136 | 1 518 | 2 757 | 778 | |

| Mining scrap | 2 053 864 | 2 298 701 | 2 274 156 | 2 292 205 | 2 423 944 | |

| OIL SHALE ASH | 1 651 832 | 1 768 186 | 1 883 510 | 1 858 566 | 1 784 323 | |

| TOTAL, IN TONNES | 3 707 202 | 4 070 819 | 4 160 100 | 4 154 014 | 4 209 392 | |

| Reuse of waste rock, tonnes | 2 053 864 | 2 203 129 | 2 093 845 | 1 753 048 | 2 324 390 |

Deposition of waste

VKG Oil (ash and oil shale) and VKG Energia (gas purification waste) deposit the generated industrial waste in a production waste landfill. An increase in the amount of deposited waste over recent years has been caused by the fact that the closure of the national hazardous waste landfill has been completed and there is currently no demand for the reuse of ash.

The amount of the waste deposited at a landfill by VKG decreased in 2020–2021. This was due to the reduced production volumes of the Kiviter and Petroter plants.

QUANTITIES OF DEPOSITED WASTE (TONNES)

- Semi-coke

- Oil shale ash (Petroter)

- Gas refinement waste which includes hazardous waste (Energia)

Waste disposal charges

Upon depositing waste in a landfill, companies pay a disposal charge. The disposal charge paid by VKG has been growing since 2015, as there has been no demand for the reuse of oil shale ash and semi-coke. The said waste is therefore fully deposited.

Pursuant to the regulation of the Minister of the Environment, “The procedure for classification of waste and the list of waste”, oil shale ash is no longer classified as hazardous waste as of 1 January 2020. The change was inspired by a study commissioned by the Ministry of the Environment, which found that oil shale ashes should no longer be classified as hazardous waste, but should be treated as ordinary waste. In connection with that, the oil shale ash disposal charge was temporarily reduced in 2020. However, the previous disposal charge is again applicable from the beginning of 2021.

WASTE DISPOSAL CHARGES (EUR)

- Semi-coke

- Oil shale ash (Petroter)

- Gas refinement waste which includes hazardous waste (Energia)

Use of resources

Extraction of mineral resources

The resource necessary for the production of shale oil is mainly obtained from VKG Kaevandused the active extraction activities of which take place on the basis of three extraction permits: KMIN-055 (Ojamaa), KMIN-066 (Sompa) and L.MK-333465 (Viru II).

With regard to extraction permit L.MK/333343 (Uus-Kiviõli II), an environmental impact assessment has been initiated in connection with amendments to the permit.

In 2020, VKG Kaevandused had permission to extract a maximum of 3,472,000 tonnes of geological stock under all the permits, of which 3,293,000 tonnes were extracted. In addition to the extracted geological stock, extraction losses are also taken into account when paying the resource charge. Together, these form extracted mineral resource stock and mineral resource stock made unfit for use. In 2020, a total of 4,360,000 tonnes of oil shale was extracted and made unfit for use and in 2021 it was 4,549,000 tonnes.

QUANTITIES OF EXTRACTED OIL SHALE

(MILLION TONNES)

Energy efficiency

The efficient use of energy resources allows us to achieve greater productivity levels, optimise industrial processes and reduce the negative impact on the environment.

In saving energy, we focus on the following:

- promoting energy management and certification pursuant to the requirements of international standard ISO 50001;

- training the personnel in the area of energy management and energy efficiency;

- new programmes and technologies aimed at saving energy;

- implementation of digital projects;

- exchange of experience with other enterprises in our sector of the economy.

VKG energiatõhusus

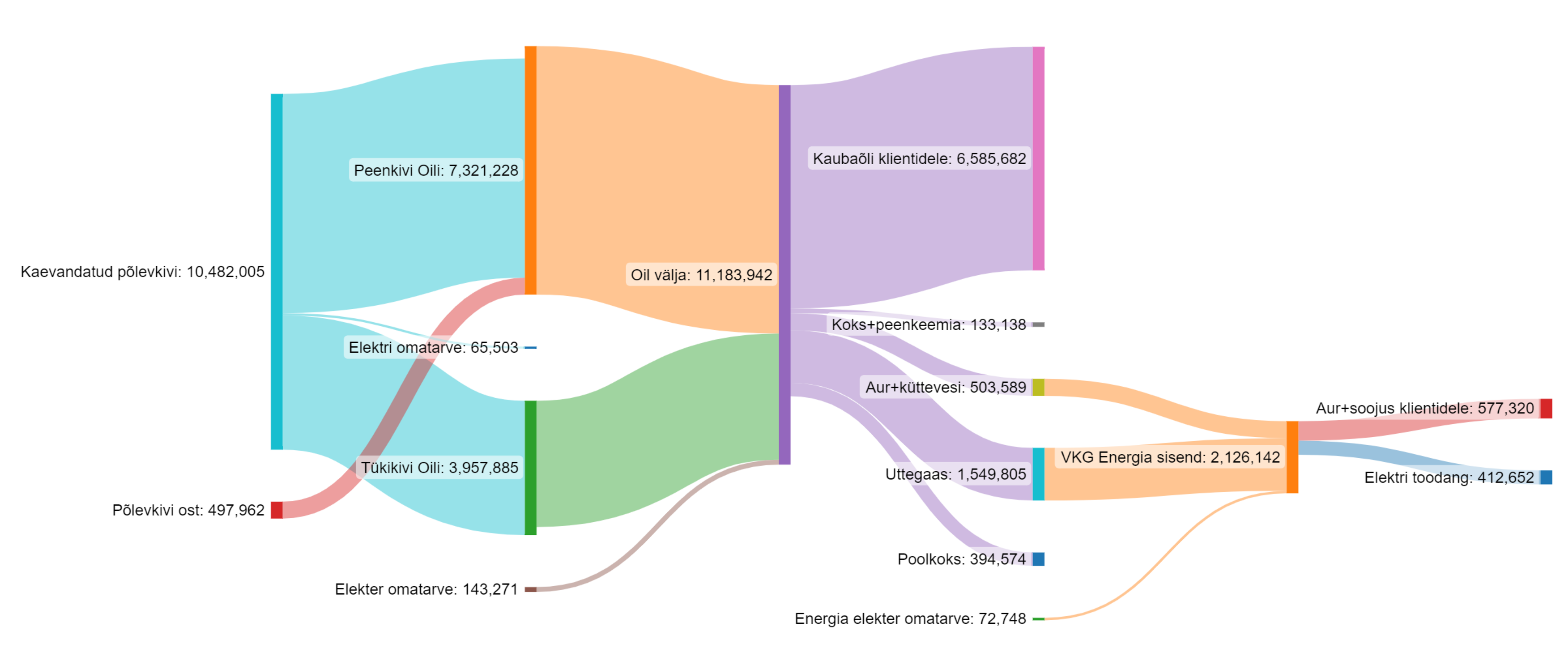

In 2021, oil shale was extracted in a quantity that corresponds to 10,482,005 MWh of energy, from which the following was produced:

- 6,585,682 MWh of oil products,

- 133,138 MWh of coke and fine chemistry products,

- 577,320 MWh of steam and district heat,

- 412,652 MWh of electricity.

The Group companies produced 7,708,792 MWh of products from the extracted oil shale. In 2022, the energy efficiency of using the oil shale resource was 73.5% at VKG.

Energy production and consumption

VKG’s steam, heat and electricity production is based on the side products generated in the course of processing oil shale: retort coal gas, steam, and heat. Retort coal gas is used for producing electricity for the Estonian power network and district heat for the cities of Jõhvi and Kohtla-Järve with controlled production equipment at VKG Energia. The enterprises located in the region are supplied with steam.

In 2020, the amount of energy produced by VKG Energia decreased from 2019, remaining on the same level as in 2018; the 2021 energy production remained on a similar level. The proportion of heat and energy production is above all influenced by the needs of the heat consumers and the volume of oil shale processing.

With regard to district heating, the heat sales volume of VKG Energia mainly depends on the weather and, with regard to steam, the customers’ consumption needs. The own consumption of heat is primarily influenced by the volume of oil shale processing and that cannot be significantly altered in an economically feasible way. Thus, the main energy efficiency measures are aimed at reducing electricity consumption.

Energy produced by VKG Energia (MWh)

- Heat and steam produced

- Electricity produced

Electricity consumption in the Group

VKG’s electricity consumption has steadily decreased in recent years. The whole Group monitors energy consumption in accordance with the principles of ISO 50001. An energy consumption measurement system has been developed across consumers and consumption optimisation solutions have been prepared for production sections and equipment with higher consumption needs. By using energy in a more optimal manner, we increase the oil shale valorisation level and improve the management of the production process, thereby reducing the risks of production interruptions. Modern measurement and control systems have also been installed on production equipment. For instance, the Coriolis meter project and the installation of additional variable speed drives on rotating equipment.

VKG’S ELECTRICITY SALES AND CONSUMPTION BALANCE UNTIL 2021 (MWh)

The largest environmental projects in the past year

Reuse of plastic waste

In cooperation with Kiviõli Keemiatööstus, we initiated a joint project in which they will use the existing shale oil production technology to process plastic waste into oil and gas. The focus will be on plastic waste which contains mixed and contaminated plastics. The industrial test plant could be ready in five years at the earliest, solving the ever-increasing plastic waste problem in line with circular economy principles. Thanks to the developed technology, the plant will be able to process up to 130,000 tonnes of plastic waste a year. In 2021, the cooperation partners carried out extensive preliminary work, started applied research and announced several international procurements to find testing and design partners.

Bioproducts production complex

On 25 August 2021, the Lüganuse rural municipality initiated the special spatial plan for VKG’s bioproducts plant. VKG is exploring possibilities of establishing a bioproducts production complex in Ida-Viru County. The plant would start adding value to paper wood which is left unused in Estonia and is currently being exported or burnt for energy, and to produce. One output of the production complex would be green energy solutions. The bioproducts production complex would start producing renewable electricity and provide green heating energy to the cities of Kohtla-Järve and Jõhvi. This complex would contribute to taking a step forward in diversifying the economy of Estonia and Ida-Viru County as well as in achieving the environmental goals and the ever increasing global demand to move towards the increased use of bioproducts.

Aidu solar park

In 2021, VKG started exploring possibilities of establishing a solar park with the installed capacity of 38 MW in the territory of the former Aidu quarry.

Shale oil filtering equipment

The shale oil filtering equipment at VKG Oil AS allows eliminating various sources of emissions to air, reduce emissions and production losses. As a result of applying a new technological scheme, no more hazardous liquid waste – fusses – is generated, but the process produces fine-dispersed ash-rich fuel and a pyrolysis residue from the thermal processing of oil shale, which can be reprocessed into shale oil and sold outside the Group.

Landfills

In 2019, we held negotiations and in 2020 concluded an agreement with the Ministry of the Environment for the disposal of waste from the recovery of residual contamination – contaminated soil and sediments – at a landfill. We also reached an agreement on joining VKG’s depositing area to a part of the state’s landfill.

Preparatory work and studies for the new landfill commenced in 2019. At the end of 2020, a special spatial plan of the Lüganuse rural municipality and a strategic assessment of environmental impact were initiated for VKG’s new industrial waste landfill project. In 2021, an independent expert prepared the initial outline of the pre-selection of the location in the context of the local government designated spatial plan as well as the memorandum of intention to conduct a strategic environmental assessment, the public display of which was held from 1 December 2021 to 31 January 2022.

The company is constantly engaged in the prevention of the potential environmental impact of the landfill. In 2020, it invested 79,000 euros in road watering and maintenance transport.

De-oiling equipment

2021 saw the reconstruction of de-oiling equipment the task of which is to purify the water of the territory of oil shale processing waste. New flotation equipment allows us to better pre-clean industrial waste water from various mechanical additives and ensure the required water quality in the drainage of the oil extraction junction. We also focused on reducing emissions to air from the said equipment.

Action plan for reducing odour

In 2019, we continued the implementation of the action plan for reducing odoriferous substances and invested into the reduction of air emissions of the shale oil tank truck loading device. We continued with the action plan for reducing odoriferous substances in 2020, performing the last measurements of the levels of odoriferous substances to assess the results of the measures taken so far, and conducted an inventory of emission sources. In 2021, we started the grand-scale reconstruction project of Petroter I, as a result of which VKG’s impact on the quality of atmospheric air in Kohtla-Järve and the vicinity is significantly reduced in 2022. In 2021, VKG Oil made an investment into reducing emissions from the breather systems of the Petroter I-II tanks and phenol water treatment tanks, which means a reduction of emissions of airborne organic compounds by up to 3.4 tonnes a year.